Heat-not-burn (HNB) technology is changing the tobacco sector. It provides a milder heating option compared to old-school burning methods. These tools warm up tobacco rather than setting it ablaze. As a result, they cut down on nasty side products. At the same time, they keep the taste and nicotine flow intact. Yet, fine-tuning the user’s satisfaction in this field brings tough design hurdles. Key spots for better results involve even heat spread and air flow control. Uneven warmth can mess with the flavor, vapor thickness, and how well the stick gets used. On top of that, weak air flow setup might cause tough pulls or extra heat buildup. This hurts ease of use and protection. The piece below looks at how stuff like material choices, machine parts, and sensor setups come together to fix these problems.

What Materials Play a Crucial Role in Achieving Heating Uniformity?

Choosing the right stuff for heat parts forms the base of good work. Folks often pick metals like stainless steel. Why? Because they handle heat well and resist rust. This lets them move warmth fast and smoothly. Newer ceramics help too. They stay steady with heat and block it where needed. So, they fit for exact temp checks without quick wear over many uses. These items need to handle repeated heat shifts without getting worn out. They should keep steady resistance levels. Plus, they must show little delay in response. Their skill in hitting goal temps fast and holding them shapes the vapor steadiness and stick output.

Why Is Precision Temperature Control So Important in HNB Systems?

Spot-on temp handling matters a lot in HNB setups. Tiny sensors placed close to the heat area feed ongoing info. This lets small computer chips tweak power supply on the fly. Such a feedback circle keeps the tobacco in the best warmth zone. It skips weak vapor or burning spots. If temp control slips, you get patchy warm areas. That hits nicotine flow, taste quality, and user safety. Smart temp plans also save power. They supply just the right amount of energy for each puff moment.

How Does Heating Chamber Geometry Affect Vapor Output?

The shape of the heat chamber directly shapes how heat spreads through the tobacco stick. A tight chamber that boosts touch points gives steady warmth over the whole stick. This setup leads to reliable vapor making. It avoids cool or overly hot patches. Even the inner surface feel and built-in shapes guide heat movement. Tweaking these bits lifts the sameness of every use. In turn, that raises user joy and cuts down on waste.

How Does Airflow Engineering Define User Experience in HNB Devices?

Air flow planning goes beyond just letting users breathe in. It decides how well the warmed tobacco turns to vapor. Well-guided air spreads heat energy across the stick. Thus, it cuts hot spots in one area. Meanwhile, it ramps up vapor yield. Air paths also cool things down before the inhale. This boosts comfort. Yet, it doesn’t weaken the vapor strength. Getting this balance right means users get easy pulls. They enjoy steady taste with little bother.

What Structural Elements Ensure Efficient Air Movement Through an HNB Device?

The inside build of air paths has to keep pull resistance low for happy users. But it also needs some limit to mix vapor well. Often, folks add filters and mesh parts. These catch big bits, shield inner pieces from gunk, and steady the air push. Smart vent spots let out extra pressure to stop overheat. At the same time, they hold a clear vapor route. All these bits team up for a natural yet polished pull feel. That’s what top HNB tools deliver.

Does Tobacco Stick Composition Influence Device Airflow?

Differences in stick tightness, cut style, or water levels can change air flow a lot. Too-packed sticks might block pulls or lessen vapor. Loose ones lead to air gaps and spotty warmth. To fight this, makers set standard sizes, water amounts, and mix of materials for sticks. Matching device needs with stick traits is key. It ensures steady work over different lots.

Which Innovations Are Driving Performance Gains in Modern HNB Devices?

Fresh device types now use smart heat chambers with double soak power. Newer versions can take in two times more heat from the stick stuff. This lifts vapor making while keeping even temps over use rounds. The change not only amps up taste strength but also helps battery life. It does so by shortening warm-up per session.

What Role Do Smart Sensors Play in Adaptive Heating Control?

Today’s HNB tools more and more add built-in sharp sensors with clever control plans. These watch room conditions, puff counts, and how users act right away. The plans use this info to shift power based on past habits. With smart plans and sharp sensors, live puff tracking shows progress and patterns. This aids health tracking and cuts worry. Such custom touches keep taste steady. They also stretch device life via power savings.

Why Is Modular Design Becoming Essential for Maintenance and Longevity?

Easy upkeep counts for lasting user like. Modular builds with removable heat parts or chambers make cleaning simple. They cut stop time from gunk slowdowns. Modular setups let makers add later tweaks. Think new heat tech or light screens. No full redo needed. This boosts product life worth. It also fits user tastes.

Who Offers Trusted Supply Solutions for HNB Device Manufacturing?

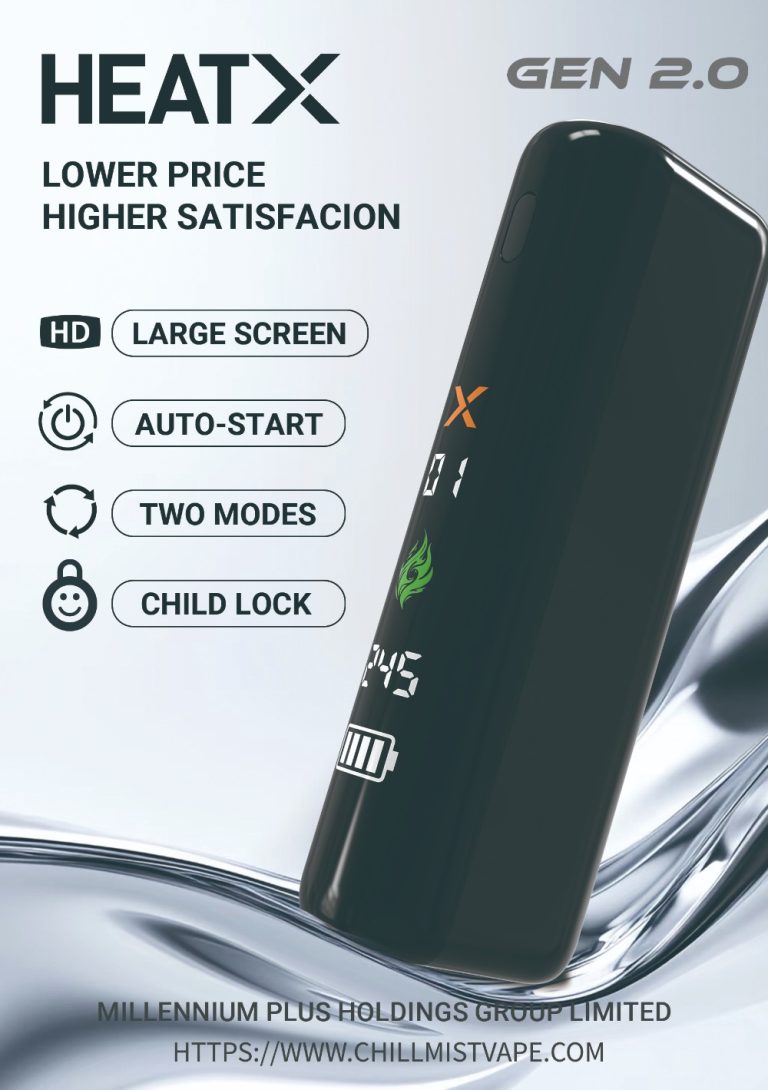

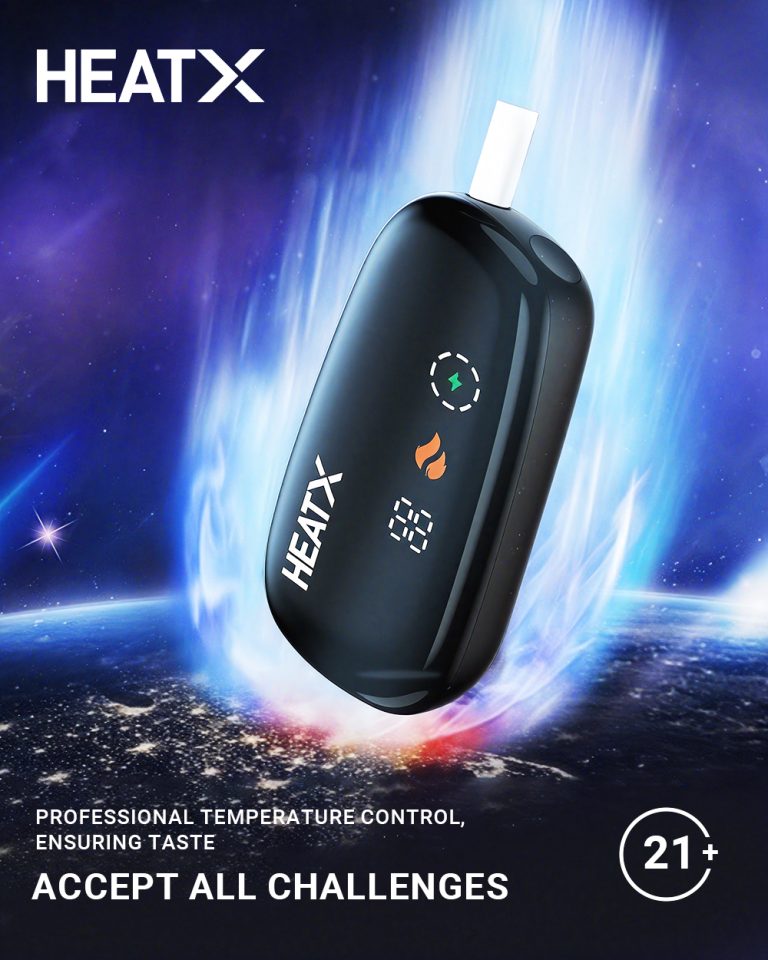

The firm puts money into research, safety, and user feel across its line. From smart heat controls to strong making rules that match world standards, their full supply options fit high-output markets. Their top all-in-one HNB tool has a 360° resistive heater, two-step heat options (20s preheat), live LED info like puff count and mode show, super-small 48g weight, 1350mAh battery for up to 15 sticks per charge, and 90-minute Type-C charge. It sticks to strict Japanese build rules with a yearly output of 20 million units. This comes with 45% auto work. Plus, full patent checks and optional Freedom To Operate (FTO) reports.

How Are Brand Synergies Between Atomized and Heat-Not-Burn Solutions Driving Innovation?

For those after links between e-cig tech—both vapor mist systems and warmed tobacco ones—ChillMist makes a strong example. This label focuses on mist-based delivery that pairs with heated tobacco under one company roof. Their team setup aids joint research, shared check rules, and side-by-side growth plans. These meet varied user needs in the nicotine world. Be it tuning coil mixes or shaping heat blades, shared tools speed up new ideas.

What Are the Strategic Priorities for Future HNB Device Engineering?

Coming HNB items must keep growing amid stricter world rules on smoke tests, battery guards, and label needs. Yet, users want quick warm times, comfy shapes, and easy screens like LED shows or puff tallies. New perks—like health trackers or custom warmth settings—can meet rules and wants. They do this when added carefully in checked setups.

Why Is Sustainable Material Selection Becoming a Key Differentiator?

Green choices will shape next devices. Designers look at body-friendly plastics, re-use metals, and piece-together methods that ease eco harm. All without losing strength or work. Adding green stuff aids company duty aims. It also lifts brand view among green-minded buyers. They seek top work plus duty.

FAQ

Q1: What makes the new HEATX device capable of absorbing twice as much?

A1: The new model incorporates advanced heating element materials with higher thermal conductivity and an expanded surface area within the chamber, allowing it to absorb more heat energy efficiently from each tobacco stick.

Q2: How does improved airflow contribute to a better HNB experience?

A2: Enhanced airflow ensures even vaporization of the tobacco material, improves flavor consistency, reduces draw resistance, and prevents overheating—leading to a smoother overall user experience.

Q3: Are ChillMist e-cigarettes related to HEATX products?

A3: Yes, both ChillMist (atomized e-cigarettes) and HEATX (heat-not-burn devices) are owned by the same parent company—Shenzhen Qianhe Technology/Millennium Plus Holdings Group Limited—and share a common focus on innovation, quality control, and user-centric design through shared R&D resources.