In recent years, the heat-not-burn market has been shifting rapidly, and this shift has pushed both manufacturers and large-scale wholesale suppliers to rethink how durable devices should be built. As expectations rise, many suppliers—especially those working closely with brands like ChillMist—have begun exploring more refined production methods. They test new structural ideas, compare different material combinations, and make small but meaningful adjustments to everyday components. Because of these ongoing efforts, the industry is moving toward sturdier, more consistent devices that match real-world usage patterns. This steady progress forms the foundation for the broader improvements discussed below.

Advancements in HNB Device Durability by Wholesale Suppliers

The Strategic Role of Wholesale HNB Suppliers in 2025

As you move through the changing world of heat-not-burn (HNB) technology, wholesale suppliers hold a key position in forming the future of device strength. These important players push forward new ideas by stressing lasting results. They make sure the items you count on can handle tough conditions over time. Market needs now lean toward stronger and more dependable tools. So, suppliers put effort into studies and growth to match what you want. Their work goes beyond just matching others. It sets fresh benchmarks. In business today, standing out depends on building toughness into product ranges. This means, as a company or user, you gain from tools made to survive hard everyday tasks. Such a focused plan makes sure the HNB options you choose are not only modern but also sturdy enough for constant work challenges.

Engineering for Durability: Materials and Structural Innovation

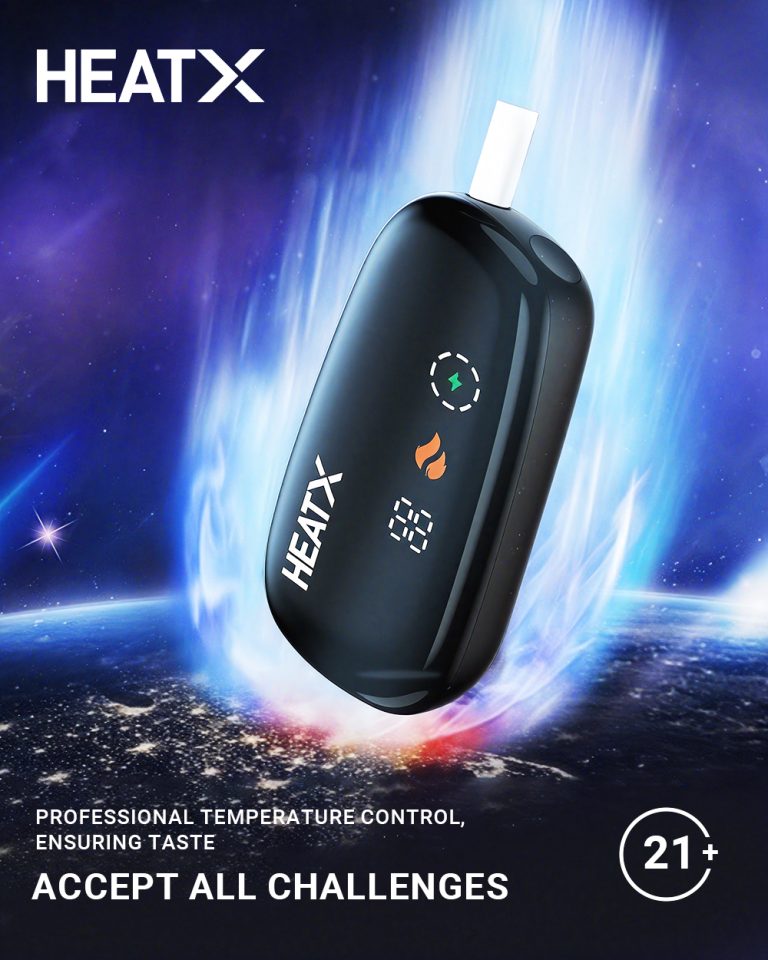

Building tools that last requires careful picks in materials and build style. For example, HEATX uses a compact 81×44×27 mm casing and a lightweight 48 g body, which helps reduce drop-impact stress over long-term daily use. Its pebble-shaped ergonomic shell also spreads pressure more evenly across the hand, lowering accidental slip risks—small details that influence real-world durability. Suppliers use top-quality metals and plastics to fight against damage, rust, and heat wear. This keeps your HNB tools working well even in rough settings. Inside, stronger setups handle the physical pressure from regular handling, so early failures are less common. Exact making methods cut down on part breakdowns. Over time, these improvements reduce the need for frequent device replacements.

Heat Management Technologies and Their Impact on Longevity

Importance of Thermal Regulation in HNB Device Lifespan

Good heat control matters a lot for stretching the life of your HNB tools. One example is HEATX’s 360° resistance-based heating technology, engineered to warm tobacco evenly across the full chamber. This uniform spread lowers localized heat spikes, which are known to accelerate material fatigue. The heater stabilizes temperature shifts in real time and keeps heat variance low throughout a session. Its 20-second preheat time reduces stress buildup on internal components, as heating cycles start and stabilize quickly. With proper thermal flow, inner parts avoid unnecessary strain, leading to a longer lifespan.

A Case of Thermal Innovation

One clear way to handle heat uses special tech that improves heat spread in the warm area. Better clay parts keep even warmth with little change. This cuts the pressure from heat ups and downs. As a result, key parts last much longer. Your tools keep working for bigger periods. When you look for balances between work and strength, these new ways give a real edge. Heat problems won’t hurt your daily use.

Battery Optimization for Extended Device Use

Enhancing Battery Life Through Intelligent Power Management

Battery strength forms a main base for tool lasting power. Suppliers improve it with smart energy handling. In the durability category, HEATX integrates a 1350mAh cell, a capacity large enough to support about 15 tobacco sticks per charge. This performance level is well above many compact HNB units in the same size class. Its Type-C charging system fills the battery in roughly 90 minutes, minimizing long-term degradation from excessive fast-charge stress. With a stable battery housing and protective layers to resist external shocks, the device maintains output consistency without forcing unnecessary load onto internal circuits.

A Focused Approach to Battery Engineering

Big-store lithium-ion units made for often use now fill high-end HNB lines. Safe covers guard these batteries from hits and outside harm. You don’t need to stress over outer things hurting work. This smart building keeps your tool powered for more time. It backs your wants without always needing new charges or swaps.

Component Integration and Modular Design Principles

Benefits of Modular Architecture in Device Longevity

Modular building changes how you care for and update your HNB tools. In units like HEATX, the integration of a clear LED screen and an internal puff counter adds practical value while keeping internal components organized and easy to service. These modules—battery, heating chamber, control board—are tightly arranged but accessible, providing a balance between compact design and simplified maintenance. This setup lets you keep gear current with little work while extending real product lifetime.

A Framework for Modular Engineering

Tools with clip-together parts for warming, battery, and control give great ease. Special links make sure tight fits. They also allow simple take-apart for fixes or adds. This setup lets you keep gear current with little work. Strength comes without losing the ability to change.

Quality Assurance Protocols from Wholesale HNB Suppliers

Multi-Level Testing Processes to Ensure Durability Standards

Suppliers use step-by-step check methods to make sure your HNB tools hit top strength levels. For instance, HEATX products are manufactured under a system with a 45% automation rate and an annual production capacity of 20 million units. Each batch undergoes strict inspections aligned with standards used by major international tobacco companies. Internal labs run accelerated aging tests to confirm long-term reliability. In addition, multi-country third-party certifications and FTO (Freedom to Operate) reports ensure product safety and durability, reducing risk for distributors and resellers.

Robust Quality Control Infrastructure

Inner labs run fast-age tests to check long-run trust. Every tool works the same as time goes on. Each batch faces auto scans and hand looks. No small thing gets missed. This strong promise to quality makes sure the HNB tools you add to your work are made to last.

Software Integration to Support Hardware Longevity

Firmware Stability as a Component of Device Durability

Software helps keep hardware strong over time. Usual wireless updates boost work without hurting body parts. Your tools run even. Built-in check tools spot early problems. You can fix them before they grow. This forward way keeps gear in best shape. It cuts stop times to almost none.

Enhancing Durability Through a Software Ecosystem

Special base code that sets warm cycles to fit outside settings improves tool run for your place. User input in updates makes work better as days pass. This mix of code and body parts boosts strength to the max. You pull the best from each piece.

After-Sales Support and Service Infrastructure

The Role of Service in Sustaining Product Longevity

Post-buy help matters for keeping HNB tool life going. Quick care stops small troubles from turning big. Easy reach to swap parts lets use go past the first promise time. For you, it builds a link that lasts way after you buy. It backs your ongoing wins.

Commitment to Long-Term Client Success

Special business-to-business teams give skill lessons and problem fixes. They help you handle things fast. A world-wide ship setup brings quick part and swap sends. It cuts breaks in your work. This full help setup makes sure your spend on HNB tech stays safe for years ahead.

Contacting a Leader for Durable HNB Solutions

Partnering with a Proven Wholesale HNB Supplier

If you’re looking for strong HNB answers fit to your wants, teaming with a solid supplier counts a lot. Straight talks open ways to make-your-own or design-your-own work chances. Custom fixes handle area rules and use needs.

A good pick is HEATX under Shenzhen Qianhe Technology. Its HNB line gains from the firm’s big study and make setup. ChillMist, which works on mist e-cigarettes, and HEATX, key in heat-not-burn tools, sit under the same group. This gives team-ups a broad tech pool and bendy make tools.

As a quick-rising new maker in the HNB field, HEATX stresses real strength boosts. These include full-round even warming, big-store batteries, good heat rule, and money-save double-breath help. They aid firms in meeting growing user hopes for trust and work. If you’re growing work or fixing product sets, HEATX’s group can back your wants. It makes sure toughness and lasting worth in 2025 and later.

FAQ

Q: How do wholesale suppliers contribute to the durability of HNB devices?

A: Wholesale suppliers push strength by stressing new materials, better heat handling, and strict quality checks. They put study and growth first to match market calls for steady tools. You get goods made for long-run work through tough builds and strong post-buy help. This focus helps create devices that stand up to daily wear and tear. Suppliers work hard to blend cutting-edge features with reliable builds. In the end, their efforts mean you can trust your HNB devices for consistent use over time.

Q: Why is thermal regulation important for HNB device longevity?

A: Thermal regulation stops too much heat, a top reason for tool breakdown. By keeping even warmth and good heat spread, suppliers make sure your tools run steady as time goes. It cuts strain on inner parts and stretches full life. Without proper control, heat can build up quickly during use. This leads to faster wear on key elements like heating coils. Good regulation keeps everything balanced. It helps avoid costly fixes down the line.

Q: What benefits does modular design offer for HNB device maintenance?

A: Modular design makes fixes and adds simple by letting you swap just needed parts. You skip tossing the whole tool. This cuts waste, drops costs, and lengthens gear life. It turns into a green pick for ongoing use. With easy access to components, maintenance becomes a quick task. You can update features as tech advances without big spends. Overall, it keeps your HNB devices fresh and functional for longer periods.