When you pick a vaping product, you want the flavor to remain the same. You expect the vapor to feel just right. And the whole experience should match what you had at the start. But behind this easy use sits a tough production process. It needs to mix safety, solid engineering, and firm rules from regulators. Not many firms keep this mix steady. That is why picking a good supplier really counts.

Take ChillMist as one clear case. This firm focuses on tech and has strong research and development skills. It also runs tight quality checks. The company employs many engineers. It offers good OEM/ODM services. And it follows global rules well. ChillMist has earned praise for making vape and heat-not-burn devices. These products show steady work, careful material handling, and designs that think of users first. What makes them stand out is their focus on ongoing new ideas. They cover choices in materials to coil building, battery protection, and machine-based assembly. All this aims to ensure steady results for clients around the world and for people who use the products.

If you dig into how they keep quality up, you see why steady output is more than just a goal in making things. It is a promise that covers every part of the process. This goes from basic supplies to heat methods and air flow setups. This piece looks at the main problems makers face. It explains how current engineering fixes them. And it gives real examples from products. These help show how the fixes work in everyday use.

Why Ingredient Safety Requires Your Attention

Steady results always start with the basic parts. If e-liquids or tobacco stuff change in how clean they are or what they contain, the vapor can shift a lot. This affects flavor alone. But it also hits safety. Rules around the world demand clear lists of what is inside. They also call for tight limits on bad stuff mixed in.

The Challenge Behind Material Stability

Your device depends on liquid or tobacco fill. Even small changes, like in thickness, nicotine amount, or water in natural leaves, can change how heat works. Makers need to use checks at many steps. This makes sure each group of materials acts the same when it turns to vapor.

Good setups test material groups before making starts. They watch them while putting together. Then they check samples in the final box. This matters a lot for devices that give steady vapor over many thousands of pulls.

How Heating Technology Affects Overall Performance

Heat systems form the core of any device. If the heat setup or the way it controls temperature wavers, your vapor might seem too light. It could feel too rough. Or it may change from one pull to the next.

Uniform Heating Is Essential for Taste Stability

Getting even heat spread is harder than it seems. Lots of devices warm from just one area. This leads to uneven pulling out of flavors. You get ups and downs in taste. This happens more with thick materials. It also shows up when the device handles several uses.

Look at the CMD001 for a real case. It uses a firm heat plan. This keeps the temperature steady, even in long sessions. When heat stays even, the vapor feels smooth. It repeats well. So you get the same feel each time.

For people who use it, this means no need to change how you breathe in. You do not fix for light or strong pulls. The device takes care of the steady part for you.

Maintaining Consistency During Large-Scale Production

As needs rise, makers have to grow fast. But growing brings dangers. Changes in how coils form, how parts tighten, how welds press, or how software sets can add small differences. Users begin to spot these over time.

Why Automation Matters

Just using people to put things together cannot keep things exactly the same. Machine-run lines help a lot. They focus on key spots like making coils, shaping plastic parts, and building circuit boards. This cuts down on small errors.

When a place uses machines to assist, mistakes get fewer. For those who buy, this leads to some benefits.

Fewer defective devices

Reduced leaking or airflow mismatches

More predictable vapor output

Firms with solid machine use make batches that work better. This makes your choice to buy more sure.

Battery Reliability and Device Safety

Battery strength is a top worry for users. If power from the battery jumps around, heat steadiness drops. And if safety steps fail, it can lead to big risks in how it runs.

Designing a Safe and Reliable Power System

A firm power base has a few key parts.

Overcharge protection

Thermal monitoring

Current regulation

Consistent cell quality

Devices with good battery handling keep power even when the level falls. This stops sudden drops in vapor. It also avoids a burned taste at the end.

That is why devices with smart power balance feel better over the full time you use them.

Product Experience as a Core Part of Quality

What users feel goes beyond just vapor. It covers how the controls work, how it fits in your hand, how buttons respond, and how air flows easy. Any change in these makes the product seem less steady as time passes.

Innovative Multi-Function Devices Require Extra Care

Items with new add-ons need hard tests under pressure. The CMD020 shows this well. It has options like touch power changes, links to Bluetooth, music play, and game modes.

For something that does more than make vapor, each part must run smooth. It should not mess with battery steadiness or heat accuracy. Reaching this mix calls for exact software tweaks, tests for how parts work with signals, and checks on how mechanics hold up.

For users, this brings a fun way to use it with many senses. Yet it still keeps the vapor steady.

Product parameters

| Size: | 23mm*50mm*100mm |

| Electronic liquid capacity: | 15mL |

| Resistance | 0.8Ω |

| Number of suction ports: | up to 18000 Puffs |

| Battery capacity: | 950mAh |

| Charging port: | Type-C |

Why Airflow Engineering Determines the Smoothness of Each Puff

How air moves sets the path for vapor in the space. Even the top heat setup cannot fix bad air flow design.

What Happens When Airflow Is Not Optimized

Issues like rough pulls, changing pull strength, or stuck paths often come from a few causes.

Uneven interior channeling

Poor mouthpiece geometry

Residue buildup patterns

Newer devices shape inside parts to cut rough air. They keep the flow smooth and straight. When air stays firm, each pull feels known and easy.

Regulatory Pressure and the Need for Global Compliance

Rules change by area. To follow them, makers keep records, test samples, and share what materials they use. Firms that sell worldwide write reports on parts. They keep labels the same. And they make sure all electric bits pass safety checks for each place.

If you get from a seller with good rule-following, you feel sure. Your device fits world safety needs. It also clears checks to bring in your area.

If you’re looking for strong HNB answers fit to your wants, teaming with a solid supplier counts a lot. Straight talks open ways to make-your-own or design-your-own work chances. Custom fixes handle area rules and use needs.

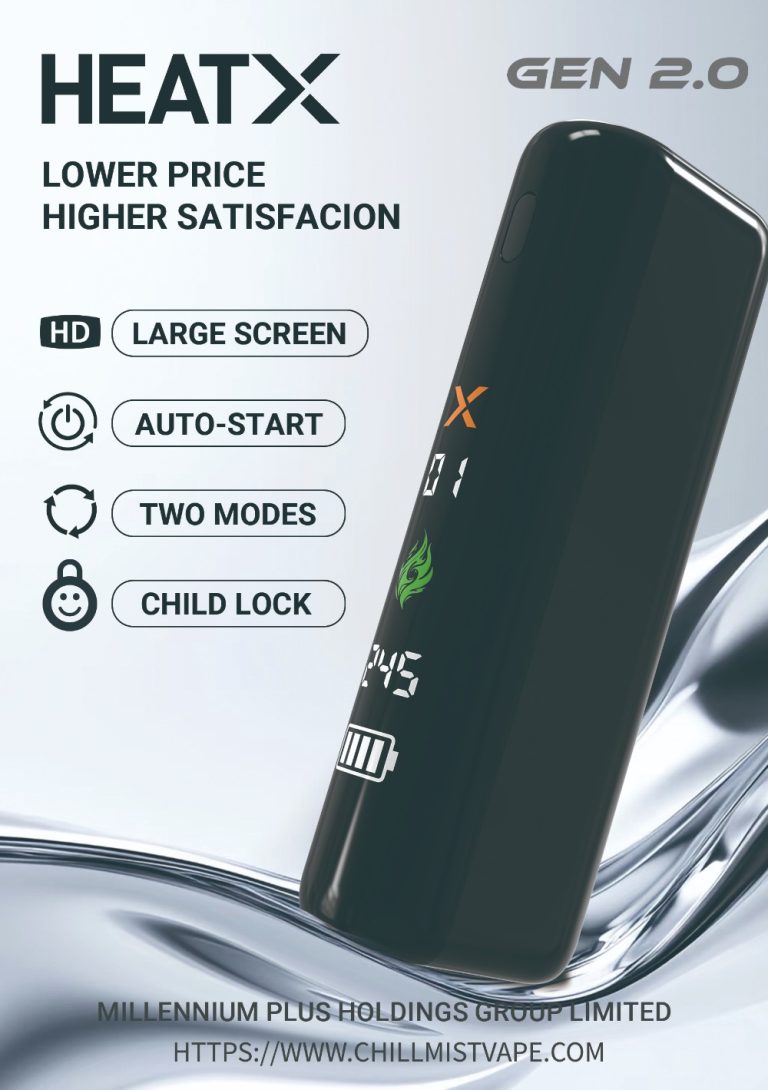

A good pick is HEATX under Shenzhen Qianhe Technology. Its HNB line gains from the firm’s big study and make setup. ChillMist, which works on mist e-cigarettes, and HEATX, key in heat-not-burn tools, sit under the same group. This gives team-ups a broad tech pool and bendy make tools.

FAQ

Q1. Why does vapor taste change over time?

A: Taste shifts happen due to changes in how full the material is, heat levels, or air pull strength. Devices made with even heat and controlled materials give flavor that holds better in each use.

Q2. How can you tell if a device has reliable battery management?

A: A device with good battery care keeps heat steady even when power is low. It has clear safety steps. And it skips quick changes in vapor power.

Q3. What should you look for when choosing a device for long-term use?

A: Seek items from places with good machines, solid material checks, better heat setups, and a history of following rules. These traits lead right to steady work.